Lightweight, durable, and economical, plastic is an integral part of modern life and has a far better environmental profile than many might think, using fewer resources to produce and transport than any other alternative. The fact is, that if manufactured and used responsibly, plastic is the most sustainable choice for many applications including protective packaging.

More concerned with genuinely reducing our environmental footprint rather than being ‘seen to be green’ we are environmentally conscious through all of our thoughts and actions. With over 30 years of experience producing quality packaging products, we have proudly held an ISO 14001 Environment certification since 2009. To maintain this certification, we must consistently adhere to an environmental management system that provides assurance that our environmental impact is being measured and continually improved.

We have pledged to achieve 30% average recycled content across all our packaging products by 2025. Our entire range of thermal bags, wraps, and carton liners now contain 20% minimum recycled content.

In line with the Australian Packaging Code of Conduct, we have pledged to achieve 30% average recycled content across all our packaging products by 2025. Most recently through environmentally focussed process and product development, we have been able to achieve an increase from 15% to 20% minimum recycled content across our entire range of thermal bags, wraps and carton liners!

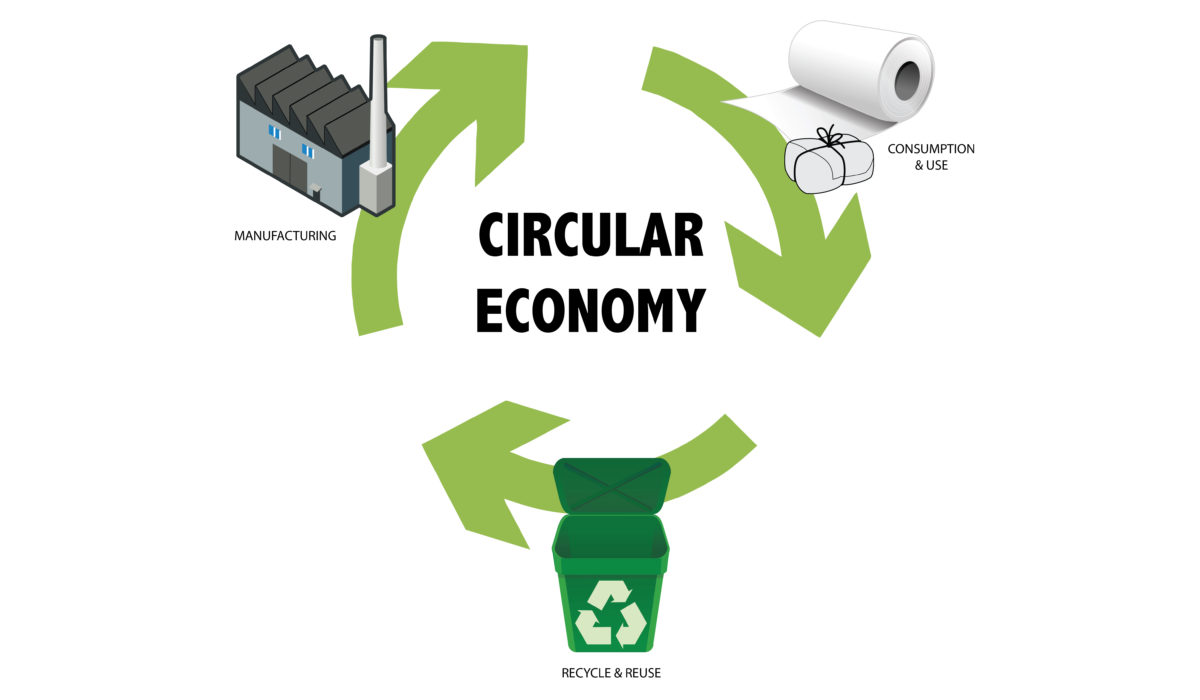

The Australian manufacturing economy is predominantly linear, otherwise known as a ‘take, make, use and, dispose’ model. At Sancell we do things differently and implement circular economy business principles, and we have done so now for some time. In line with Planet Ark’s business recycling guidelines, we replace ‘dispose’ with ‘reduce, reuse, recycle and repurpose’ with the aim to keep plastic in circulation for as long as possible and out of landfill.

We have our in-house recycling stream meaning we recycle 80% of our waste from production using our recycling machine and feed this back into many of our stock line products. In fact, we do such a good job of recycling our own waste, we often need to buy in outside waste to recycle so we can maintain the minimum recycled content we have committed to in our products. All our products contain a minimum of 15% recycled content (up to 40% in some cases). We produce larger rolls to reduce the number of trucks on the road and our entire factory and offices are fitted with low energy LED lighting.

By implementing Circular Economy business principles, we replace ‘dispose’ with ‘reduce, reuse, recycle and repurpose’ throughout all of our thoughts, actions and processes.

With water being one of our most valuable resources here in Australia and doing our part to ease

From a consumer point of view, recycling of our products is made easy. The majority of our packaging products are made using LDPE plastic meaning it is 100% recyclable with soft plastics. With over 2000 drop off points conveniently located nationwide at supermarkets, consumers have a convenient and accessible way to recycle our products.

At our manufacturing facility based in Melbourne all our products are proudly made right here in Australia. There are numerous benefits to buying Australian made including shorter time frames, easier communication, higher manufacturing standards and retention of Australian jobs. But many overlook the fact that it also significantly reduces the environmental impact of what your buying by requiring less transportation to deliver and therefore producing far less pollution.

And finally by creating the highest quality products that are made exactly to specification and fit for purpose, first time every time, we further reduce our environmental impact by minimising waste and production costs for both us and our customers.

When it comes to the complex challenge of minimising our environmental impact, we are absolutely determined to look at every option possible and embrace multiple solutions that have an impact both now and into the future.